Filling and Capping Systems

Everything from manual, to semi-automatic, to fully automated filling and capping systems. All kinds of containers—glass, plastic, metal, or foil. All kinds of caps. We cover it.

Bottle Unscramblers

Bottle unscramblers are designed to prepare bottles to move down the line, completing multiple functions in the process:

- Sort - Unscramble plastic bottles supplied in bulk

- Print - Ink or laser code the bottoms of bottles

- Recirculate - Infeed glass bottles or brite stock (filled, unlabeled)

- Reject - Remove bad product before discharge

- Position - Place, orient, gap and stabilize bottles

- Inspect - Vision system to read codes & associate serialized data

- Air Rinse - Remove bottle particulate with an ionized air rinse

- Insert - Feed canister desiccants into bottles before discharge

- Label - In-chute bottle labeling before discharge (low speed)

SRP - Servo Unscrambler with Rotary Pockets

- 100% positive control of the bottle

- Premium construction and soundproofing

- Servo motion & advanced controls package

- Option to integrate advanced functions

- Air rinse, desiccant feeding, ink or laser coding, reject handling

- Open design for easy access and cleaning

- Rapid, repeatable changeovers

- Accommodates wide range of bottles

LCX - Unscrambler with Rotary Pockets

LCX - Unscrambler with Rotary Pockets

- 100% positive control of the bottle

- Advanced controls package

- Open design for easy access and cleaning

- Rapid, repeatable changeovers

- Accommodates wide range of bottles

PRP - Unscrambler with Puck Handling System

- 100% positive control of the bottle

- Handles many complex bottle shapes

- Various infeed configurations available

- Open design for easy access and cleaning

- Rapid, repeatable changeover

LB - Unscrambler with Fixed Pockets

- Minimal moving parts

- Ideal for dedicated, high speed lines

- Open design for easy access and cleaning

- Sturdy construction

- Fully automatic operation

Cyclone - Unscrambler with Built-In Hopper

- Speeds up to 120 bottles per minute*

- 5-minute, repeatable changeover

- Save floor space with built-in hopper

- Easy to operate and maintain

- Fully automatic operation

Vantage - Unscrambler with Direct Placement

- Bottles exit sorter in upright position

- Bottles feed into a starwheel or Monoblock

- Vantage is a standalone unit or can integrate with your Monoblock

- Option to integrate bottle labeler in the chute

- Slim design; Occupies minimal floor space

- Simple to operate and maintain

- Fully automatic operation

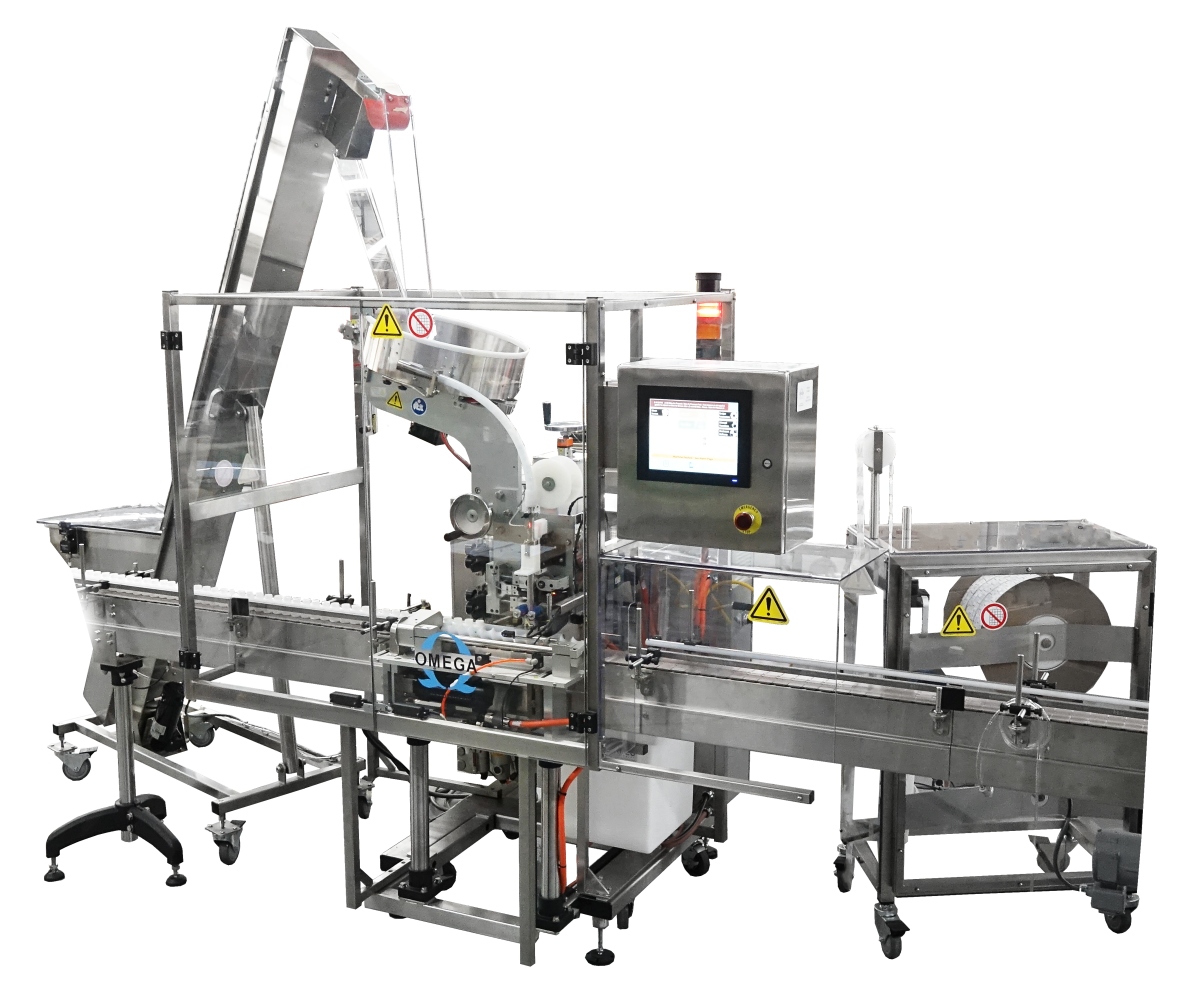

OmegaSort - Belt-Style Bottle Unscrambler

- Various machine configurations available

- Easy adjust belt pulleys for bottle variations

- Non-marring, FDA-approved belting

- Rapid, repeatable changeovers

Omni-Feeder - Servo Feeder for Pouches and Canisters

- Adjusts for pouches or canister desiccants

- Adjusts for single or multiple drops

- Adjusts for different desiccant sizes

- Handles many brands (Clariant, Sanner, Multi-Sorb)

- Servo-controlled, fully automatic operation

- Rapid, repeatable changeovers

- FDA-approved contact parts

PDF - Servo Pouch Dessicant Feeder

- Adjusts for single or multiple drops

- Adjusts for different desiccant sizes

- Handles many brands (Clariant, Sanner, Multi-Sorb)

- Servo-controlled, fully automatic operation

- Rapid, repeatable changeovers

- Upgradeable for canister desiccants

- FDA-approved contact parts

Econo PDF - Pouch Dessicant Feeder

- Adjusts for single or multiple drops

- Adjusts for different desiccant sizes

- Handles pouches from major manufacturers

- Uses stepper motor; all electric (no air needed)

- Fully automatic operation; simple setup

- Rapid, repeatable changeovers

- FDA-approved contact parts

CDF - Canister Feeder, Star Wheel Style

- Adjusts for single or multiple drops

- Adjusts for different desiccant sizes

- Handles many brands (Clariant, Sanner, Multi-Sorb)

- Fully automatic operation

- Rapid, repeatable changeovers

- FDA-approved contact parts

- Dispense desiccants or oxygen absorbers

CDFS - Canister Feeder, Shuttle Style

- Adjusts for single or multiple drops

- Adjusts for different desiccant sizes

- Handles canisters from major manufacturers

- Patented Shuttle System (no bottle-specific change parts)

- Rapid, repeatable changeovers

- Compact, mobile frame

- FDA-approved contact parts

- Dispense desiccants or oxygen absorbers

Cap Pre-Feeders

Elevators requiring only minimal floor space keep your line supplied with caps. Multiple hopper and elevator sizes are available.

Cap Sorters

Cap Sorters

Multiple sorting options can accommodate any type or size cap:

- Vibration

- Centrifugal

- Elevator

Some systems require little to no changeover for different caps.

Capping Systems

Threaded, press-on, induction, or some combination, we offer both spindle and chuck style options for a wide range of bottle (2–14″) and cap (10–115 mm) sizes.

Liquid Filling Systems

From small (1/4 oz.) to large (5 gal) fills. From low to high volume. From 2 to 20 or even more fill heads. Gravity, gravity plus pressure, pumped, or overflow filling. Fill by time or volume. No matter what viscosity. Whether your application requires high-temperature filling, a sanitary environment, or involves corrosive products, we offer equipment that can do the job.