Stay up to date with our latest news.

Technical Packaging Systems is committed to offering the industry’s best selection of high-quality, durable, and cost-efficient packaging systems and materials. Supplying customers with some of the biggest names in the industry, we carry equipment from Markem-Imaje, Ohlson, Wexxar Bel, Lantech, Anritsu, Garvey, Softech Engineering, and more. With a wide range of our products on display during our annual Pack Expo, you can get firsthand – and hands-on – experience with all of our equipment. Best of all, you can learn from industry experts exactly why – and how – this equipment can benefit you, your employees, and your operation.

If you’re in the market for shrink wrappers, conveyors, labelers, cartoners, inspection systems, or any number of other packaging systems, you’re in luck! The 2019 TPS Pack Expo is being held on June 26th and 27th from 10:00 AM to 5:00 PM. A good opportunity to take a closer look at the industry’s best packaging equipment, the expo affords visitors the ability to see, learn about, and interact with top-of-the-line machines. Whether you’re looking to open a new facility or you want to upgrade your current line, the TPS Pack Expo is a great chance to get some hands-on experience and – more importantly – advice from industry experts.

When it comes to marking and coding, Markem-Imaje is an industry leader and, with their model 9028, they’ve provided customers with an inkjet printing system that is fast, efficient, versatile, and reliable. As a trusted manufacturer of traceability solutions, Markem-Imaje has built their reputation around offering high-quality inkjet, laser, thermal transfer, and label application systems. Continually seeking to improve their products, they operate a number of global research and development centers and manufacturing plants. In today’s post, we’re going to take a closer look at the model 9028, discuss its capabilities and explore how it can improve efficiency on your production line.

When you need the absolute best case former, there’s no better source than Technical Packaging Systems. With an experienced sales team and a catalog of the industry’s top packaging equipment, you can be confident that you’ll find exactly what you need. Better still, if you’re unsure about your needs, our team will work with you to understand the challenges that you’re facing and then identify potential solutions. Whether you’re running a single small line or a massive manufacturing facility, we’re here to help! In today’s post, we’re going to discuss the BEL 5252u semi-automatic form, pack, and seal system.

If you’re looking to improve your operation’s productivity, hot melt inkjet printers from Markem-Imaje are a proven method. With the ability to deliver superior print quality coding solutions for your corrugated cases, trays, and wrapping films, they are utilized by the industry’s best because they are rock-solid reliable and highly efficient. Whether you’re a small operation looking to increase production to the next level or a massive production facility struggling to keep up with demand, these printers can help to ensure that your line continues moving. In today’s post, we’re going to look at a handful of the benefits offered by Markem-Image’s inkjet printers.

With a reputation for high-quality, dependable equipment, Trinamics manufactures the industry’s best case packers. No matter what products your packing or what you’re packing them into – cartons, trays, or bags – you can be confident that Trinamics’ packers offer unparalleled versatility combined with a compact, space-friendly footprint. More importantly, you can be certain that they’ll get the job done. Having earned recognition for their innovative designs, Trinamics’ packers promise better packaging efficiency and productivity, as well as reduced maintenance and labor costs.

At Technical Packaging Systems, we’re always excited to hear about new additions to Lantech’s line of high-quality stretch wrappers. Recently, they added the QL-400 to their LeanWrap® series. The QL-400 is billed as an “intelligent, intuitive, and instructional semi-automatic stretch wrapper.” Bundled with interactive applications that make it a breeze to build new wrap profiles, the QL-400 reduces your machine’s dependency on operators, allowing your staff to focus on more productive – and profitable – tasks.

On December 4, 5, and 6, Technical Packaging Systems will have a double booth at the Michigan Greenhouse Growers Expo, exhibiting the IPAK model TF 330 tray former and the Markem Imaje model 9450 small character product coder. If you find yourself near the Devos Place Convention Center in downtown Grand Rapids, we would love to see you there! Whether you’re looking to improve and streamline your manufacturing operation or you’re simply interested in the fascinating topics discussed at the expo, you’re sure to have a great time. Let’s take a closer look at the products that we’ll be showing off at our booths!

Technical Packaging Systems is committed to affording our customers access to the absolute best products and services. Whether you’re looking for stretch wrappers, bagging systems, jet printer inks, premium shrink films, or other equipment and supplies that are essential to your operation, you can be confident that we can deliver. With over 30 years of experience and a staff of highly trained professionals, we have helped customers in a range of industries – from pharmaceutical to automotive – with all of their packaging and material handling needs.

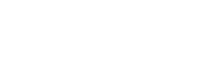

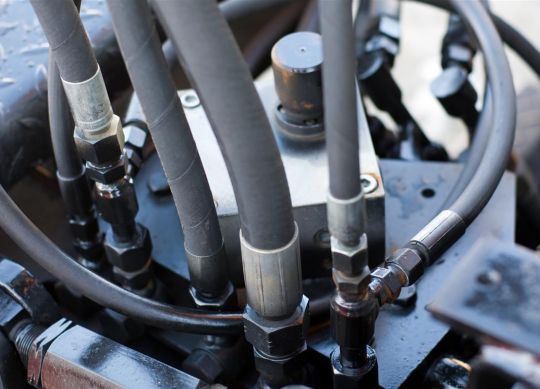

If you’re having trouble with your line’s equipment, rest assured that Technical Packaging Systems can help by providing experienced, cost-saving packaging machinery technical service. As a packaging and material handling distributor and integrator that operates in nearly every industry, we’ve seen – and addressed – it all. With the assistance of our well-trained technicians, you can be confident that your line will be up, running, and productive in no time flat. In today’s post, we’re going to look at a few of the reasons why you should consider Technical Packaging Systems when it comes time to service your equipment.