Stay up to date with our latest news.

Do you find yourself constantly moving products from one area of your facility to another? Are you fighting the friction of metal tabletops as you slide your products from one place to the next? Or worse, are your employees wasting valuable time transporting products by hand? If the answer to any of these questions is yes, you are in a great position to save time – and money – with Triton's Chain Driven Live Roller Conveyors (CDLR). Ideal for moving tires, drums, pallets and other unwieldy items, Triton's conveyors are world-renowned for their ruggedness, versatility and ease of use. In this post, we're going to look at how your operation can benefit from utilizing a Triton conveyor.

Stretch films are very diverse in terms of thickness, pre-stretch, different additives and resins, and also how the film is extruded. The two different techniques used to create stretch film are blown and stretch. Each of these techniques used to create the stretch film will yield different properties – and depending on your application – you’ll want to consider what the best fit is for you. We have laid out the quick and easy comparisons between blown film and cast film for you.

With all the modern interest in multitasking, packing machines continue to offer more and more options. However, IPak believes that there’s something to be said for doing one thing and doing it well. That’s why, with the TF-100 tray former, they have created a machine that specializes solely on forming 4-corner trays. Efficient, high-performance and easy to use, the TF-100 is an amazing value for anyone in the beverage, hygiene, pharmaceutical, electronics or processed foods industries. In this post, we’re going to take a closer look at the TF-100 and discuss why it’s a great option for customers that have limited floor space, a limited budget or limited experience with tray forming machines.

In the world of manufacturing, case forming is its own bottleneck. You can be great at manufacturing, assembling and quality testing your product, but if you fall short on getting it packaged, you’ll fall behind in shipments and, as a result, fall below your sales expectations. Thankfully, Wexxar offers a range of case forming equipment – including the fully-automatic WF30 – that can help you match your shipping speed to your production speed. In this post, we’re going to take a closer look at the design, build and features offered by Wexxar’s WF30 high-speed case former.

Offering an unparalleled amount of flexibility, Trinamics’ TR1000 load case packer allows you to pack a number of different product configurations using the same case packer. As it is designed as a top load case packer, it offers an inherent advantage: easy redeployment in the future, should the make up or spectrum of your products change. Because of this, the TR1000 is an ideal packing solution for companies that regularly expand their product lines or redefine their line’s packing needs.

The Trinamics family of side and end-load case packagers are ideally-suited for packing a wide variety of products. Capable of being loaded through the top, bottom or end panels – depending on the nature of the case design and the characteristics of the product – they offer a degree of versatility that allows them to be adapted to your line’s specific needs. This flexibility, combined with the packers’ swift cycle rates, contributes to a more efficient, more productive and more profitable packaging line. In this post, we’re going to take a closer look at some of the advantages offered by the Trinamics TR616SL and TR616EL case packers.

The pinnacle of case packing technology, Trinamics’ TR616TL case packer is engineered to form, load and seal RSC-style cases at rates of up to twenty cases per minute. Capable of both top and bottom sealing, the TR616TL offers a degree of versatility that is virtually unmatched by other case packing equipment and, more importantly, is a surefire way to boost your operations’ efficiency.

One of the biggest difficulties with internal transportation is moving products that are unstable or irregularly shaped. Prone to tumbles off the conveyor system or – more common – getting caught up in transfer devices, these products can cause “traffic jams” on your conveyor systems and slow production to a halt.

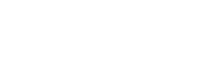

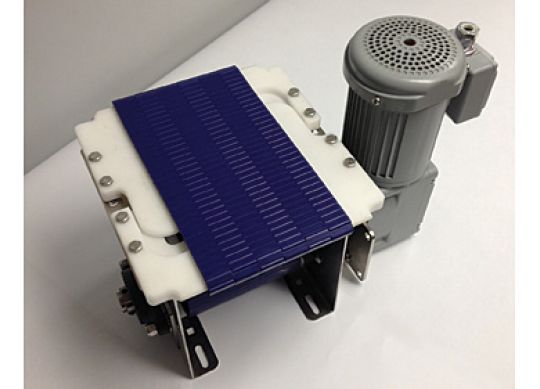

Are you working in an industry where tough, rigorous applications are unavoidable? Are you experiencing a rise of products being damaged during transport? If so, the mat-style conveyor from MCE may be just the solution that you’re looking for. Designed to provide long life and high impact resistance, MCE mat-top conveyors are capable of moving products across inclines, declines and production line curves.

If your operation requires you to transport your products throughout your facility, whether it’s before, during or after assembly, then you’re almost assuredly in the market for a high-speed, versatile transporting solution. In that case, we would encourage you to investigate the many benefits offered by the MCE tabletop conveyor.