Stay up to date with our latest news.

There’s a stark difference between how people travel and how a pallet load travels. Snug in the soft, upholstered seats of our vehicles, we move painlessly from one place to another. Pallet loads, on the other hand, must endure some of the harshest travel conditions possible: freezing cold, creeping moisture, extreme vibration and more.

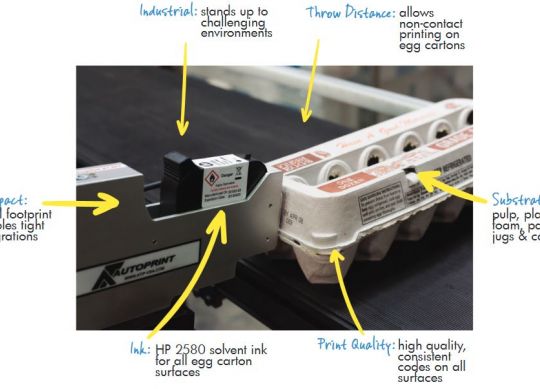

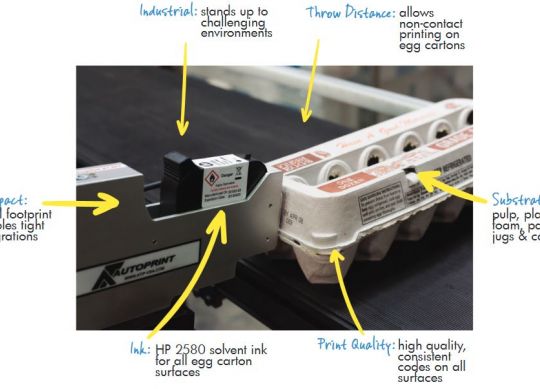

When it comes to product coding, thermal inkjet printing offers the durability and high print quality that your packaging operation requires. Capable of printing on paperboard products, plastic packaging and even curved surfaces, HP Inkjet Technology’s flexibility allows you to simplify your coding by eliminating the need for multiple print processes. In this post, we’re going to look at why thermal printing and HP Inkjet Technology have become the go-to solution for the product coding needs of a range of industries.

For more than forty years, AT Information Products (ATIP) has provided dependable, high-quality inkjet printing solutions that allow for easy product identification and hassle-free package coding. Now, ATIP has rolled out a line of black solvent ink specifically designed to print on non-porous surfaces. With the introduction of these inks, ATIP has expanded the range of possibilities afforded by industrial coding products and has lived up to their reputation as the industry’s most innovative provider of inkjet printing solutions.

Local craft breweries in Michigan and abroad are growing at astonishing rates. With increasing demand for product, comes an increase in production. Technical Packaging Systems is here to make sure that your packaging can keep up with production and demand for your product. The cost of a machine is a one-time purchase that will, over time, pay dividends.

Proper inspection, especially in regards to the removal of ferrous and stainless steel contaminants, is a major concern in the pharmaceutical and food industries. These dangerous contaminants can cause grave harm to your product's users and irreparable damage to your company's reputation. By utilizing an Anritsu metal detector in your production line, you can help to ensure that all metal contaminants are removed from your product prior to packaging and, more importantly, you can protect end users by providing a safer, more consistent product. Today, we're going to take a closer look at three of the major advantages of implementing an Anritsu metal detector into your production line.

Proper inspection, especially in regards to the removal of ferrous and stainless steel contaminants, is a major concern in the pharmaceutical and food industries. These dangerous contaminants can cause grave harm to your product's users and irreparable damage to your company's reputation. By utilizing an Anritsu metal detector in your production line, you can help to ensure that all metal contaminants are removed from your product prior to packaging and, more importantly, you can protect end users by providing a safer, more consistent product. Today, we're going to take a closer look at three of the major advantages of implementing an Anritsu metal detector into your production line.