Stay up to date with our latest news.

Driven to help their clients develop novel solutions to their manufacturing issues, APT's packaging equipment and machines are utilized globally to address a wide range of challenges. With a reputation for refusing to fail, they have proven themselves in the industry and shown their clients that they are a tenacious, hardworking company that is committed to helping their clients gain competitive advantages in their markets.

In almost every operation, productivity is influenced by the flow of materials. If you're unable to quickly process, load and ship materials from one work area to the next, an artificial bottleneck is created that severely limits your operation's production. By integrating equipment that ensures an efficient material flow, you can ease this bottleneck, increase production and, even better, promote employee safety. In this post, we're going to examine the operational and ergonomic benefits of the Schmalz vacuum lifting systems available from Technical Packaging Systems.

Are you looking to add an entry-level L-sealer to your operation? Have you considered integrating a wrapper into your production line but, unfortunately, found yourself intimidated by the cost? If that's the case, we encourage you to take a look at the 2215 Spartan L-Sealer from Texwrap. Designed to integrate into lines where space – or cost – is a concern, the 2215 Spartan is one of Technical Packaging Systems' most affordable – and most efficient – wrappers. Packed with essential features and built to the same standards that Texwrap is renowned for, the 2215 Spartan is one of the most versatile entry-level machines on the market.

Labeling your cartons and packages can be one of the most labor intensive – and expensive – aspects of your production line. If you're currently incurring the cost of labels and ribbons, you stand to save thousands by implementing a more streamlined – and better integrated – labeling system. Two products from AT Information Products (ATIP) can help reduce your costs and, even better, alleviate the burden associated with traditional labeling systems: the iJET Printer and the X1Jet AUTOPRINT system.

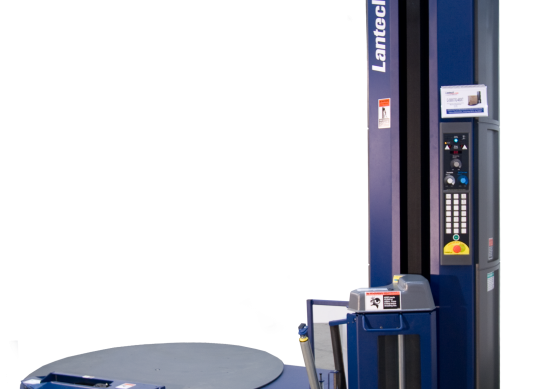

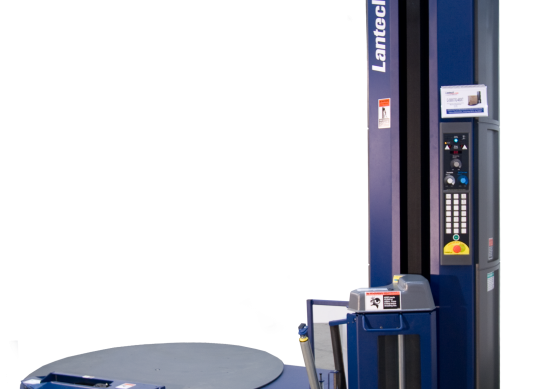

If you're considering integrating a stretch wrapper into your production line, you've undoubtedly wrestled with concerns over operator skill. With the time – and financial – investment required to properly train operators, it can be risky gambling on employees that may – or may not – stick around. This, coupled with the downtime incurred by a training period, can make the integration of a stretch wrapper seem out of reach. Well, with Lantech's new "Load Guardian" program, these concerns are a thing of the past!

Next month, October 11 to October 13, Technical Packaging Systems will be giving customers the chance to explore stretch wrapper options firsthand with our Lantech Truck Blitz. Loaded up with the company's Q400XT with the "EZ Scale" and "Click-N-Go" upgrades, this is an excellent opportunity to learn about advancements in stretch wrapper technology, as well as see these amazing pieces of equipment in action. During the event, our staff will be on hand and prepared to answer any questions that you may have about integrating new stretch wrapping equipment into your operation, such as our equipment's production speeds, maximum load weights and wrap forces.

When you buy a car, you take it for a test drive. When you pick out new clothes, you try them on. Why should purchasing packaging equipment be any different? We want to be able to show our customers how much of a difference the packaging equipment we sell can have on their operation, and why the equipment we offer is second to none. That's why we're happy to extend our Automation Summit invite to you. The event will be running from August 29th to September 16th. We will be featuring Case Forming, Tray Forming, Inspection Equipment, and many others on our showroom floor (Stretch wrapping, shrink wrapping, food sanitary conveyors, etc.).

Stretch films are very diverse in terms of thickness, pre-stretch, different additives and resins, and also how the film is extruded. The two different techniques used to create stretch film are blown and stretch. Each of these techniques used to create the stretch film will yield different properties – and depending on your application – you’ll want to consider what the best fit is for you. We have laid out the quick and easy comparisons between blown film and cast film for you.

The WF20 fully automatic case former introduces a new level of refinement and performance and raises the standards for ease of use, case forming quality, and customer value. Technical Packaging Systems is inviting anyone interested in seeing this case former in action to our facility to experience hands on testing. Our Automation Summit will run from August 29 to September 16. To sign up and reserve your time slot click here. Not only will you be able to experience the WF20 but you will also be able to see and test all of the packaging materials on our show floor.

Lauded by customers for their extreme reliability and extensive product line, IPak develops the industry’s most innovative tray formers and offers a wealth of sealing, stacking and feeding solutions. Among their catalog, the IPak TF-100 has become a cornerstone: an automatic tray former in a compact profile that is manufactured from rugged, heavy duty materials. Including all of the standard features that IPak has become known for, the TF-100 specializes in 4-corner trays, making it an ideal solution for a range of applications, including beverage, pharmaceuticals, electronics and processed foods. In this post, we’re going to take a closer look at the benefits of the IPak TF-100 and, more importantly, discuss how you can explore these benefits firsthand at our upcoming IPak Demo, running from August 29 to September 16, 2016.